Dekasyl MS-5 - Application

In order to achieve good results, the correct application of the glue is essential.

Dekasyl MS-5 sticks to many materials such as e.g. Aluminum, stainless steel, galvanized steel, zinc, copper, brass, powder coated metal and most unprimed painted metal surfaces. However, these must be dry and free of dust and grease. Dekaclean is recommended for cleaning.

Prior sanding of the adhesive surfaces is only necessary for special substrates such as ceramic-sealed paintwork and GRP.

If the components to be bonded are exposed to high thermal and physical loads, a primer such as Dekavator is still recommended. But beware. The decavator needs a ventilation time of at least 30 minutes!

Dekasyl MS-5 should be processed at a temperature of +5°C to 35°C.

The materials to be bonded must be assembled within 15 minutes (at 20°C/50% relative humidity).

If the adhesive is used for sealing, the smoothing joint must be removed within 12 minutes (at 20°C/50% relative humidity). If the temperatures are higher, the processing time is reduced. After 10 minutes (at 20°C/50% relative humidity) the adhesive can be painted over with most industrial paints.

For similar materials, an adhesive thickness of approx. 2mm is recommended, but the bond is exposed to large thermal expansion of different materials, such as e.g. Solar holder on the vehicle roof, you have to increase the adhesive thickness.

Examples of use

Elastic connections and seals

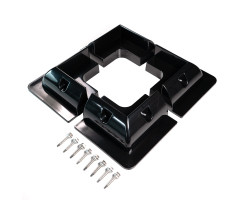

Gluing windows, AT systems, solar module spoilers, semi-flexible solar modules or roof ducts

Bonding of edge profiles for trailers with aluminum or polyester

Bonding of polyester parts with metal frames

290ml cartridge

manufacturer information:

DEKA Kleben & Dichten GmbH

Gartenstraße 4

Ranstadt, 63691

Hessen, DE

order@dekalin.de

responsible person:

DEKA Kleben & Dichten GmbH

Gartenstraße 4

Ranstadt, 63691

Hessen, DE

order@dekalin.de

There are no reviews yet.